Recognizing the Significance of Membrane Switch in Modern Electronic Devices and Their Applications

Membrane switches over act as an important part in modern electronics, using an efficient user interface for customer interaction. Their adjustable and lightweight nature makes them appropriate for a series of applications across varied markets. Comprehending their essential parts and advantages can provide insights right into their growing significance. As modern technology remains to advance, the evolution of Membrane switches questions concerning their future applications and style innovations. What exists in advance in this vibrant area?

What Are Membrane Switches?

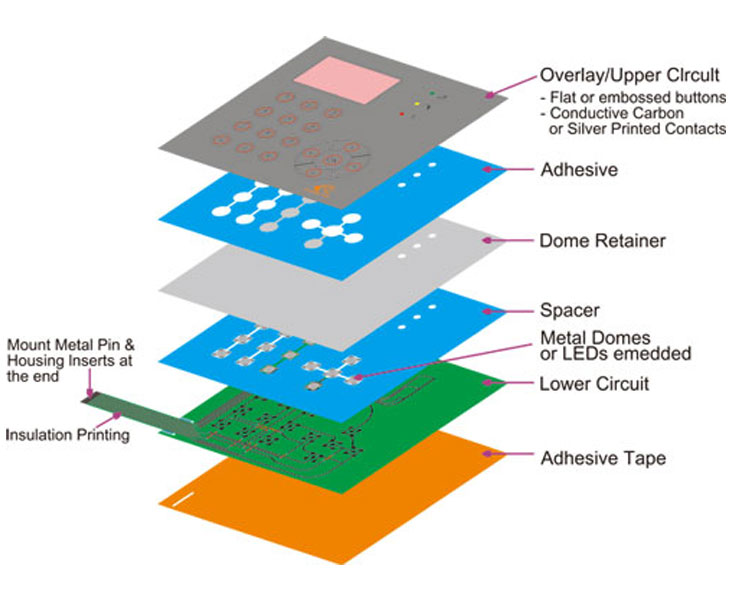

Membrane buttons are crucial parts in modern electronics, offering as user interfaces that facilitate communication in between users and gadgets. These switches contain numerous layers, including a visuals overlay, an adhesive layer, and a circuit layer, every one of which interact to produce a useful and long lasting interface. The style permits a flat, low-profile remedy that can be personalized concerning size, shape, and visual look, making them ideal for different applications, from consumer electronic devices to medical devices. The tactile responses supplied by Membrane switches over improves user experience, while their resistance to dust and wetness makes them suitable for challenging environments. Membrane buttons can integrate functions such as backlighting and published graphics, better increasing their functionality. Their versatility and toughness make them a preferred choice in markets where integrity and convenience of use are paramount, inevitably adding to the smooth procedure of contemporary digital tools.

Secret Parts of Membrane Switches

While numerous components add to the performance of a membrane switch, 3 main layers play considerable roles in its style and procedure. The top layer, generally made from a sturdy polymer, functions as the user interface for customer communication, frequently featuring published graphics and symbols. Beneath this is the spacer layer, which keeps the necessary distance between the top layer and the circuit layer. This spacer layer assurances that the switch triggers only when pushed, avoiding unintentional inputs. Lastly, the circuit layer consists of conductive traces that finish the electric circuit when the top layer is dispirited. These traces can be made from different materials, including copper or silver. Together, these components create a reputable and robust device that is compact and versatile, suitable for a vast array of digital applications, from family home appliances to clinical gadgets. Comprehending these key parts is essential for valuing the overall functionality of Membrane buttons.

Benefits of Using Membrane Changes

Membrane Switch Production Refine

Comprehending the Membrane button manufacturing process exposes the complex actions entailed in generating these crucial parts. The procedure usually starts with the layout phase, where formats and specifications are created using specialized software application. Following this, the graphic overlay is printed on a versatile substratum, typically utilizing high-resolution printing strategies to assure clarity and precision.Next, the sticky layers are applied, which serve to bond the different elements together. The circuit layers, made from conductive inks or products, are after that published onto a different substrate. These layers are thoroughly aligned and laminated to develop a useful switch.After assembly, the switches undertake checking to confirm functionality and sturdiness. Quality control measures are implemented throughout the process to identify and fix any kind of problems. Finally, the finished Membrane buttons are packaged and prepared for circulation, prepared to meet the needs of contemporary digital applications.

Applications of Membrane Switches in Numerous Industries

Membrane switches are significantly used throughout different sectors, particularly in clinical equipment and consumer electronic devices. In the medical field, they provide trustworthy control interfaces for gadgets that require specific procedure. In customer electronic devices, these switches boost user communication by supplying receptive and streamlined user interfaces.

Medical Tools Control

Various contemporary clinical tools make use of Membrane switches for streamlined operation and boosted user interaction. These switches supply a reputable, long lasting user interface for a selection of applications, including analysis devices, person surveillance systems, and medical instruments. Their customizable designs permit details layouts that can accommodate the distinct requirements of health care experts, making sure user-friendly navigating and reliable access to vital functions. Furthermore, Membrane switches are immune to impurities, making them ideal for sterile environments. The tactile responses they supply can enhance individual confidence, decreasing the risk of errors during crucial clinical procedures. In general, the assimilation of Membrane buttons in clinical devices significantly adds to boosted functional effectiveness and patient safety and security in healthcare setups.

Consumer Electronic Devices Interfaces

In the domain name of customer electronics, Membrane switches play a critical duty in boosting interface throughout a variety of devices. These buttons are essential to products such as remote controls, microwaves, and gaming consoles, providing a reliable and user-friendly user interface. Their style enables a smooth combination of graphics and functionality, allowing manufacturers to produce smooth, modern aesthetic appeals without compromising functionality. Membrane switches are likewise recognized for their longevity, typically holding up against comprehensive usage and exposure to different ecological problems. Furthermore, they can include attributes like backlighting and responsive feedback, further enhancing the customer experience. As consumer demands for advanced yet user-friendly user interfaces expand, Membrane switches remain to be a necessary part in progressing electronic gadget functionality.

Style Factors To Consider for Membrane Switches Over

Creating effective Membrane switches needs careful interest to different aspects that affect both capability and customer experience. One essential factor to consider is the option of products, as they can influence durability, tactile feedback, and visual allure. Picking an ideal adhesive is vital for guaranteeing long-term adhesion and resistance to ecological factors.In enhancement, the format and layout of the button have to suit individual interaction, with button sizes and spacing optimized for convenience of usage. The consolidation of graphics and labeling must prioritize clarity and exposure under numerous lights conditions.Consideration of electrical qualities, such as actuation force and button level of sensitivity, will enhance the responsiveness of the Membrane switch. The style ought to suit producing processes to assure cost-effectiveness and timely manufacturing. Generally, a well-thought-out design improves both the performance and the user experience of Membrane buttons look at here now in contemporary electronics.

Future Patterns in Membrane Switch Modern Technology

As technology proceeds to advance, Membrane buttons are poised to integrate brand-new developments that will certainly enhance their performance and application in numerous fields. One considerable fad is the consolidation of long lasting and adaptable materials, which will certainly increase the life expectancy and integrity of these switches. Improved surface area textures and adjustable graphics are additionally prepared for, permitting even more instinctive customer interfaces.Moreover, the integration of wise technology, such as touch-sensitive surface areas and haptic feedback, is expected to enhance individual communication, making Membrane switches over more appealing and responsive. Furthermore, breakthroughs in published electronic devices will certainly make it possible for much more complex wiring within thinner accounts, better increasing layout possibilities.Sustainability will certainly additionally play a vital function in future advancements, as makers discover eco-friendly products and manufacturing procedures. In general, these trends will certainly ensure that Membrane switches remain indispensable and relevant in a increasingly electronic and interconnected world.

Frequently Asked Questions

Just How Do Membrane Switches Contrast to Standard Mechanical Switches?

Membrane changes offer benefits over standard mechanical switches, consisting of decreased dimension, lighter weight, and enhanced toughness. They generally offer a secured surface area, enhancing resistance to dirt and moisture, making them perfect for varied applications.

What Materials Are Commonly Used in Membrane Switch Building?

Can Membrane Changes Withstand Extreme Environmental Issues?

Membrane switches can endure severe ecological problems, relying on their style and materials. Premium buildings commonly include toughness versus temperature fluctuations, moisture, and direct exposure to chemicals, making them appropriate for various demanding applications throughout markets.

The Length Of Time Do Membrane Switches Typically Last Prior To Failure?

Membrane switches over commonly show a life expectancy ranging from 1 to 10 million actuations, depending on variables such as use regularity, ecological conditions, and making high quality. Routine upkeep can prolong their sturdiness and operational integrity significantly.

Are Membrane Switches Over Adjustable for Specific Applications?

Membrane switches are without a doubt adjustable for specific applications. They can be customized in design, dimension, and performance, permitting producers to fulfill distinct customer requirements and improve item visual appeals while keeping functional efficiency and toughness. Membrane switches are necessary parts in modern electronics, offering as customer interfaces that facilitate interaction in between devices and users. The tactile comments given by Membrane switches enhances individual experience, while their resistance to dirt and wetness makes them suitable for testing environments. The incorporation of graphics and labeling ought to focus on clearness and presence under numerous lights conditions.Consideration of electric characteristics, such as actuation pressure and button level of sensitivity, will certainly boost the responsiveness of the Membrane switch. Improved surface structures and adjustable graphics are likewise prepared for, allowing for more user-friendly individual interfaces.Moreover, the combination of wise innovation, such as touch-sensitive surfaces and haptic comments, is expected to improve user why not try this out interaction, making Membrane switches extra responsive and interesting. Membrane changes deal advantages over traditional mechanical buttons, consisting of minimized size, lighter weight, and improved toughness.